News | February 16, 2026

The London appointment expands the firm’s capabilities in product safety, crisis management, materials science, risk assessment, and high-stakes failure analysis.

February 13, 2026

As the global energy landscape shifts toward sustainability, solar panels have emerged as one of the most widely adopted renewable technologies. Converting sunlight into electricity is well understood, but often the long-term performance of solar installations hinges on a complex interplay of mechanical, electrical, civil/structural and material systems. For engineers, developers, and asset managers, understanding these interdependencies is critical to ensuring reliability over the typical 20- to 25-year design life of a solar facility.

Solar panels perform best when oriented perpendicular to the sun’s rays. To maintain this optimal angle throughout the day and year, many installations incorporate solar tracking systems. Dual-axis trackers offer the highest precision, adjusting for both daily and seasonal solar movement. However, they also introduce mechanical complexity and higher maintenance costs.

The industry’s most common approach is to use a single-axis tracking, which adjusts panels east-to-west to follow the sun’s daily path. This approach can increase energy yield by 15% to 35%, but only when the system remains fully operational. Failures in actuators, often due to corrosion or poor drainage design, markedly reduce efficiency below that of fixed systems.

A case in point: actuator thrust plates without proper water drainage may perform adequately in arid climates, but in humid regions like the southeastern US, they become vulnerable to water accumulation and corrosion. This highlights the importance of environment-specific engineering, a principle that should guide both design and procurement decisions.

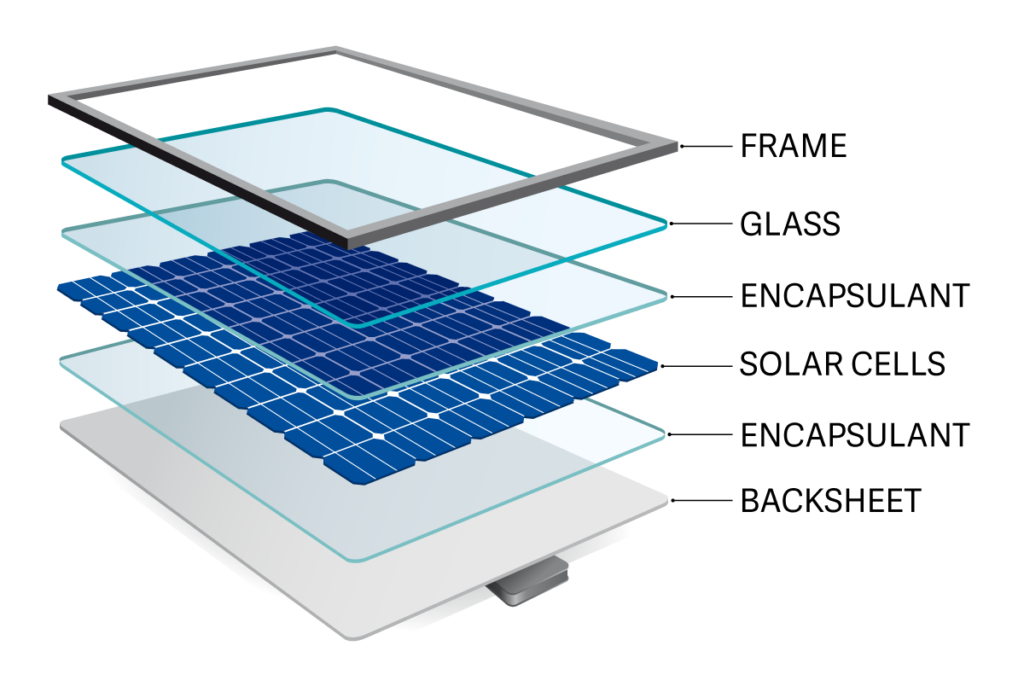

The fabrication of solar panels is a highly refined process. While new technologies are continuously being developed and utilized, the most common process begins with high-purity silicon, which is melted, crystallized, and sliced into wafers. These wafers are then textured, doped, and coated to enhance light absorption and electrical conductivity. Metal contacts are added, and the cells are laminated between protective layers before being framed for structural integrity.

Each step in this process is critical. Challenges with manufacturing or mismatches between material properties and environmental conditions can lead to efficiency losses, premature degradation, or even safety hazards such as fires. Exposure to humidity, temperature extremes, and UV radiation accelerates wear, making material corrosion resistance a cornerstone of solar reliability.

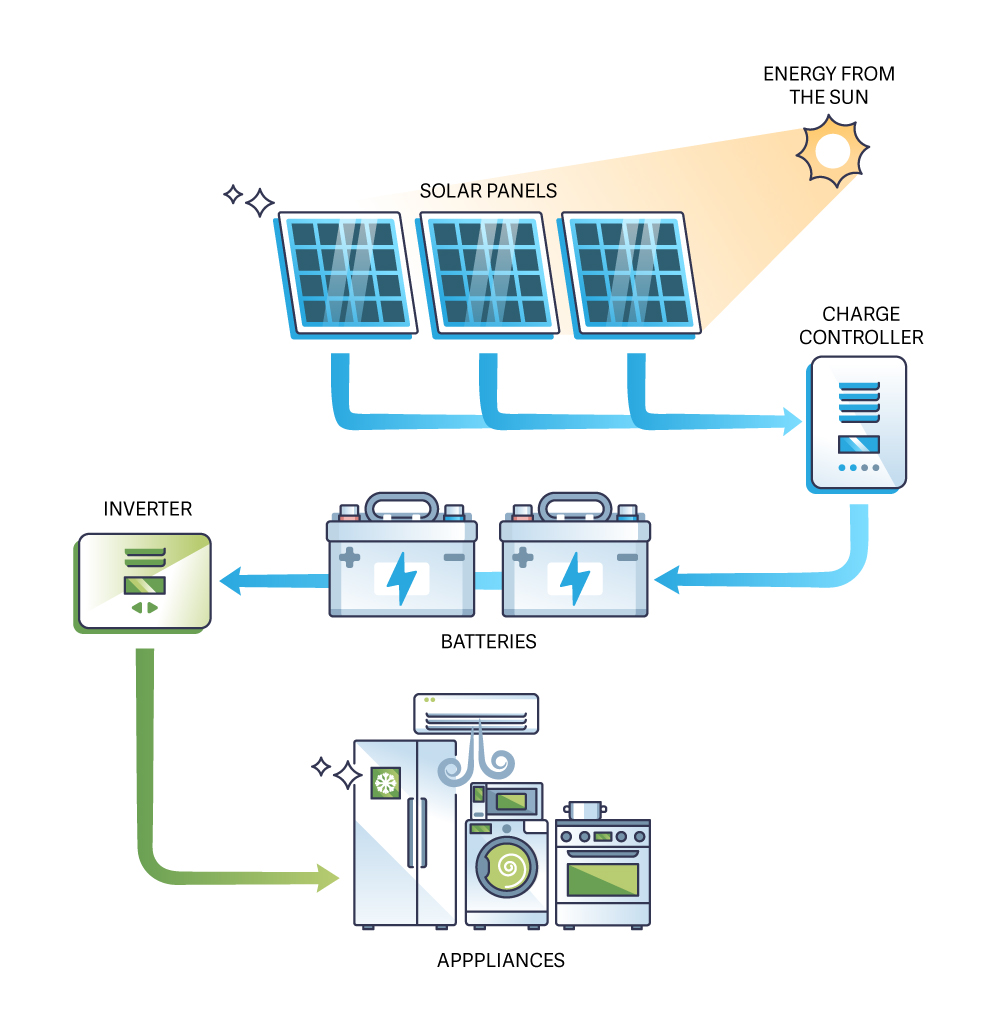

Solar panel systems produce DC voltage and use inverters to convert electrical power to AC voltage. Inverters are susceptible to fire risks and power efficiency losses through exposure to environmental conditions. Power quality can be reduced without proper synchronization of frequency and voltage. Harmonic distortions from nearby equipment can also degrade the quality of the electrical power. Monitoring the solar panel control system is key to maintaining efficiency and load balancing with battery storage systems.

Solar farms are frequently constructed in undeveloped, remote areas with little available pre-existing information about existing surface features, subsurface conditions, or site geology. Understanding the prior site development history and performing detailed subsurface investigations are critical to reducing uncertainty in anticipated conditions across these large sites and managing risks of encountering differing or unforeseen site conditions. Identification and management of these uncertainties and site risks are key elements to achieving a successful solar project design and performance.

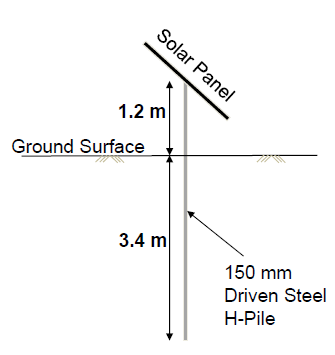

Solar panels are lightweight structures often supported on steel H-pile foundations. Various factors can impact the performance of pile foundations for solar projects. Examples include varying wind speeds for different tracking positions, the stiffness of the adjacent soil and pile, slope and erosion potential of the adjacent ground, depth to the bearing stratum, uplift forces from wind or adfreeze (frost), and corrosion. Weak axis and bi-axial bending can also control the pile design during the design wind events. Coordination of the foundation systems with the performance requirements of the material, mechanical, and electrical systems for solar projects is crucial to achieving the expected longevity for these projects.

Solar energy development is is a systems challenge. Thoughtful integration of design, environmental context, and long-term reliability must guide every phase of development. As the industry matures, the next frontier of innovation lies not just in higher efficiency cells, but in engineering resilience, ensuring that every component, from actuator to silicon wafer, is built to last.

While renewable energy systems perform critical roles, they sometimes don’t performance as intended, fail, or are at risk of failure. Secretariat’s engineers and scientists specialize in understanding why. Our industry-recognized experts conduct investigations into material failures, construction, product design, regulatory inquiries, performance issues, and disputes. We identify root causes such as design defects, human error, manufacturing nonconformances, nonconformance with codes and standards, or inadequate overall processes.

Across disciplines, regions, and industries, Secretariat’s highly-credentialed and collaborative engineering and scientific experts apply technical excellence and creativity to meet today’s most complex challenges.

The London appointment expands the firm’s capabilities in product safety, crisis management, materials science, risk assessment, and high-stakes failure analysis.

Jimmy McCutcheon Recognized as a Rising Star of the Profession by Consulting Magazine

Secretariat is proud to announce that Jimmy McCutcheon has been recognized in Consulting Magazine’s Rising Stars 2026 awards, earning recognition for excellence in Industry-Specialization.

The Evolving SEC Enforcement Landscape: Trends for 2026

The SEC’s guidance, combined with rapid technological advancement and the boom of social media, is reshaping the current enforcement landscape. This article takes a closer look at how the SEC’s enforcement priorities shifted in 2025 and what those developments suggest for the emerging risk areas in 2026.